A Guide to Manufacturing Software Systems: Boosting Productivity and Efficiency

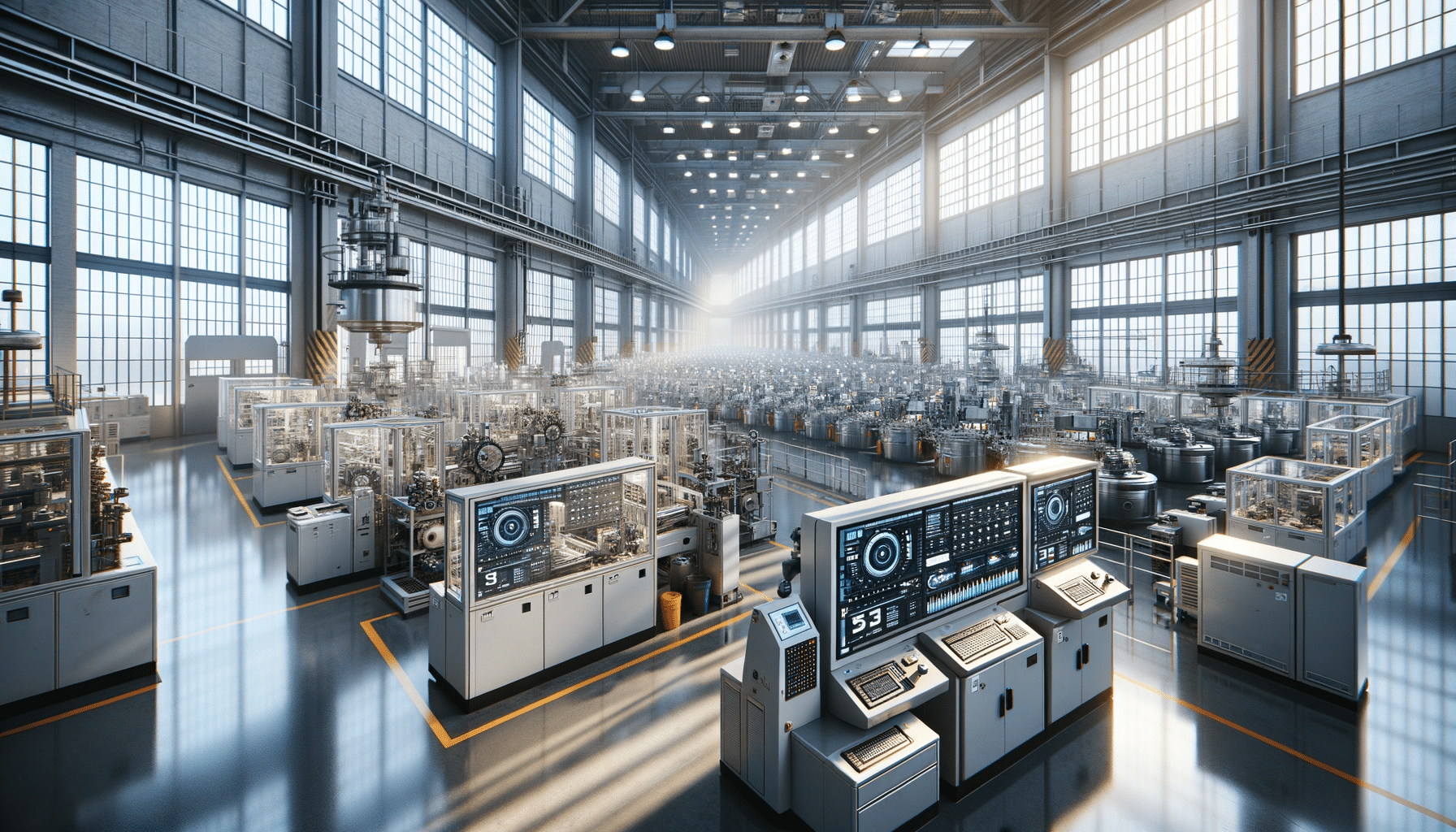

The Role of Manufacturing Software Systems

In the ever-evolving landscape of industry, manufacturing software systems have emerged as vital tools for enhancing productivity and efficiency. These systems are designed to integrate various manufacturing processes, providing a seamless flow of information across different departments. By centralizing data, these systems facilitate better decision-making and real-time monitoring, which are crucial for maintaining a competitive edge.

Manufacturing software systems are not just tools for large corporations. They are increasingly being adopted by small to medium-sized enterprises (SMEs) due to their scalability and adaptability. These systems help businesses to streamline operations, reduce waste, and improve product quality, ultimately leading to increased customer satisfaction and profitability.

Key processes integrated by manufacturing software include inventory management, production planning, quality control, and real-time monitoring. Each of these components plays a crucial role in ensuring that manufacturing operations run smoothly and efficiently. By automating repetitive tasks, these systems free up human resources to focus on more strategic activities, thereby maximizing productivity.

Inventory Management and Resource Allocation

Effective inventory management is a cornerstone of successful manufacturing operations. Manufacturing software systems provide robust tools for managing inventory, ensuring that raw materials and finished goods are available when needed without overstocking. This balance is crucial for minimizing carrying costs and avoiding production delays.

These systems use data analytics to forecast demand accurately, allowing manufacturers to plan their production schedules more effectively. By understanding trends and patterns in demand, businesses can optimize their inventory levels and reduce waste. This level of precision in inventory management is particularly beneficial in industries with rapidly changing markets or seasonal demand fluctuations.

Moreover, manufacturing software systems enhance resource allocation by providing insights into machine utilization and workforce management. By analyzing production data, these systems can identify bottlenecks and suggest improvements, ensuring that resources are used efficiently. This capability not only improves operational efficiency but also reduces the overall cost of production.

Production Planning and Scheduling

Production planning and scheduling are critical components of manufacturing operations that can significantly impact a company’s bottom line. Manufacturing software systems offer advanced tools for planning and scheduling that help businesses optimize their production processes.

These systems enable manufacturers to create detailed production plans that take into account factors such as machine availability, labor capacity, and material requirements. By using real-time data, these plans can be adjusted dynamically to accommodate changes in demand or unexpected disruptions. This flexibility is essential for maintaining high levels of productivity and meeting customer expectations.

Additionally, manufacturing software systems provide visualization tools that allow managers to monitor production workflows and identify potential issues before they escalate. By having a clear view of the entire production process, businesses can make informed decisions that enhance efficiency and reduce downtime.

Quality Control and Assurance

Maintaining high-quality standards is paramount in manufacturing, and software systems play a crucial role in achieving this goal. These systems provide comprehensive tools for quality control and assurance, enabling businesses to consistently produce products that meet or exceed customer expectations.

Manufacturing software systems offer real-time monitoring and data collection capabilities, allowing for immediate detection of defects or deviations from quality standards. By identifying issues early in the production process, businesses can take corrective actions promptly, reducing waste and avoiding costly rework.

Furthermore, these systems facilitate compliance with industry regulations and standards by maintaining detailed records of production processes and quality checks. This level of documentation is essential for audits and certifications, providing manufacturers with the assurance that their operations meet the necessary quality requirements.

Real-Time Monitoring and Data-Driven Insights

One of the most significant advantages of manufacturing software systems is their ability to provide real-time monitoring and data-driven insights. These capabilities enable businesses to respond quickly to changes in the production environment and make informed decisions that enhance efficiency and productivity.

Real-time monitoring allows manufacturers to track the performance of machines and equipment, ensuring that they are operating at optimal levels. By identifying potential issues before they lead to downtime, businesses can maintain continuous production and avoid costly disruptions.

Data-driven insights are equally valuable, providing managers with the information they need to optimize processes and improve overall performance. By analyzing production data, businesses can identify trends, uncover inefficiencies, and implement strategies that lead to higher levels of productivity and profitability.