Understanding Industrial Machines

Introduction to Industrial Machines

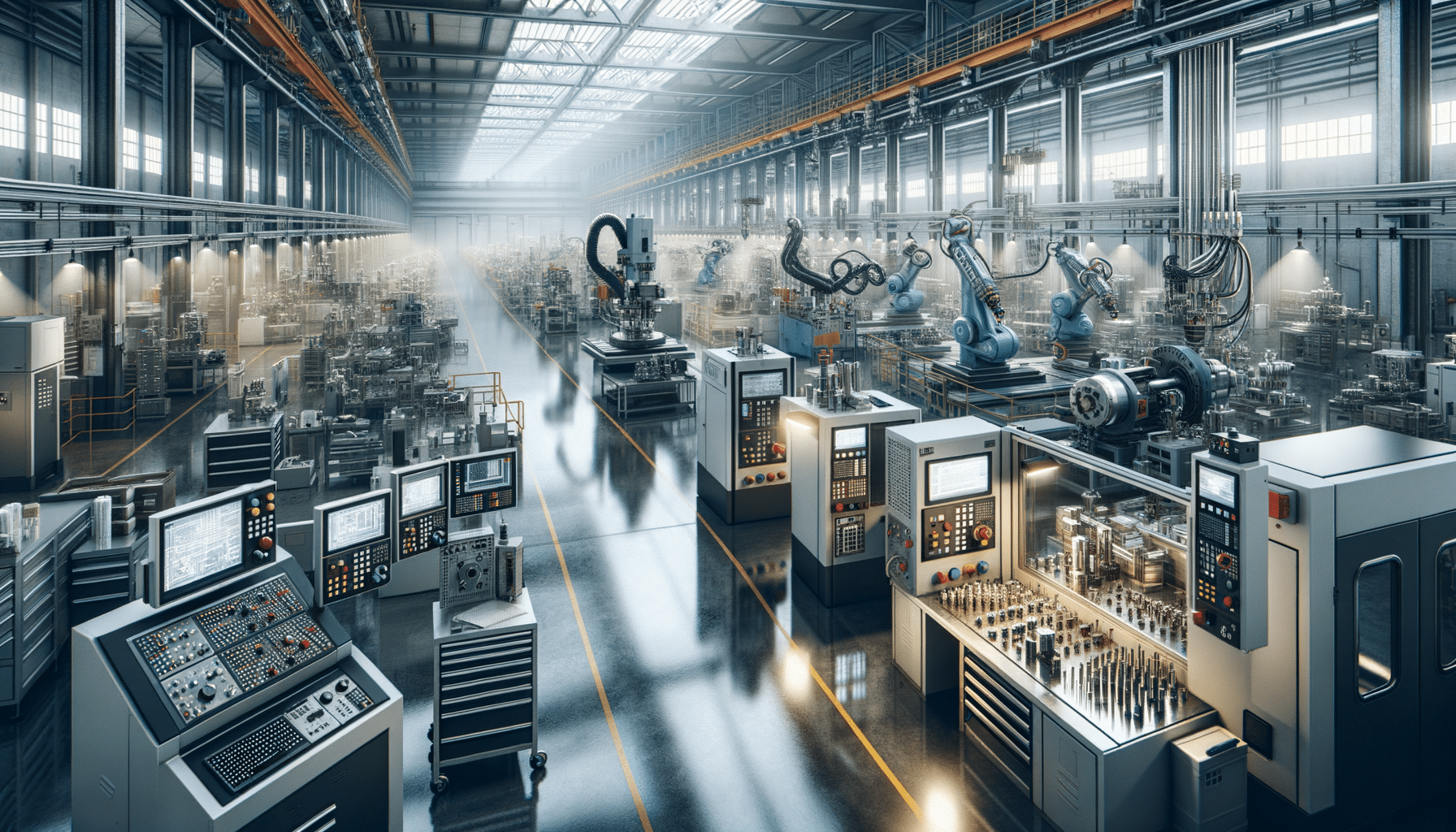

Industrial machines have been the backbone of manufacturing processes for decades, revolutionizing how products are made and enhancing productivity across various industries. Understanding these machines is crucial for anyone involved in the manufacturing sector, as they play a pivotal role in shaping the modern industrial landscape. From small-scale workshops to large manufacturing plants, industrial machines are indispensable tools that facilitate efficiency, precision, and speed.

The Role of Industrial Machines in Modern Manufacturing

In today’s fast-paced manufacturing environment, industrial machines are integral to ensuring seamless production processes. These machines significantly reduce human error, enhance precision, and allow for mass production of goods, thereby meeting the ever-increasing demands of the global market. The automation provided by industrial machines not only boosts productivity but also ensures consistency in product quality. This consistency is essential for maintaining brand reputation and meeting customer expectations.

Moreover, industrial machines contribute to cost efficiency by minimizing waste and optimizing resource use. They allow for the precise measurement and cutting of materials, reducing the likelihood of errors that could lead to material wastage. This efficiency translates into cost savings for manufacturers, allowing them to invest in further technological advancements and innovation.

Types of Industrial Machines and Their Functions

Industrial machines come in various types, each designed to perform specific functions that cater to different aspects of manufacturing. Understanding these machines and their roles can provide valuable insights into their contribution to the industry.

- CNC Machines: Computer Numerical Control (CNC) machines are used for precise cutting, drilling, and machining of materials. They are highly versatile and can be programmed to perform complex tasks with high accuracy.

- Robotic Arms: These are used for tasks that require precision and repetition, such as assembly, painting, and welding. Robotic arms improve efficiency and safety by performing tasks that might be hazardous to human workers.

- 3D Printers: These machines have revolutionized prototyping and small-scale production by allowing for the creation of three-dimensional objects from digital models. They offer flexibility and speed in producing complex designs.

Each type of machine plays a unique role in the manufacturing process, contributing to the overall efficiency and effectiveness of production lines.

Innovations and Future Trends in Industrial Machinery

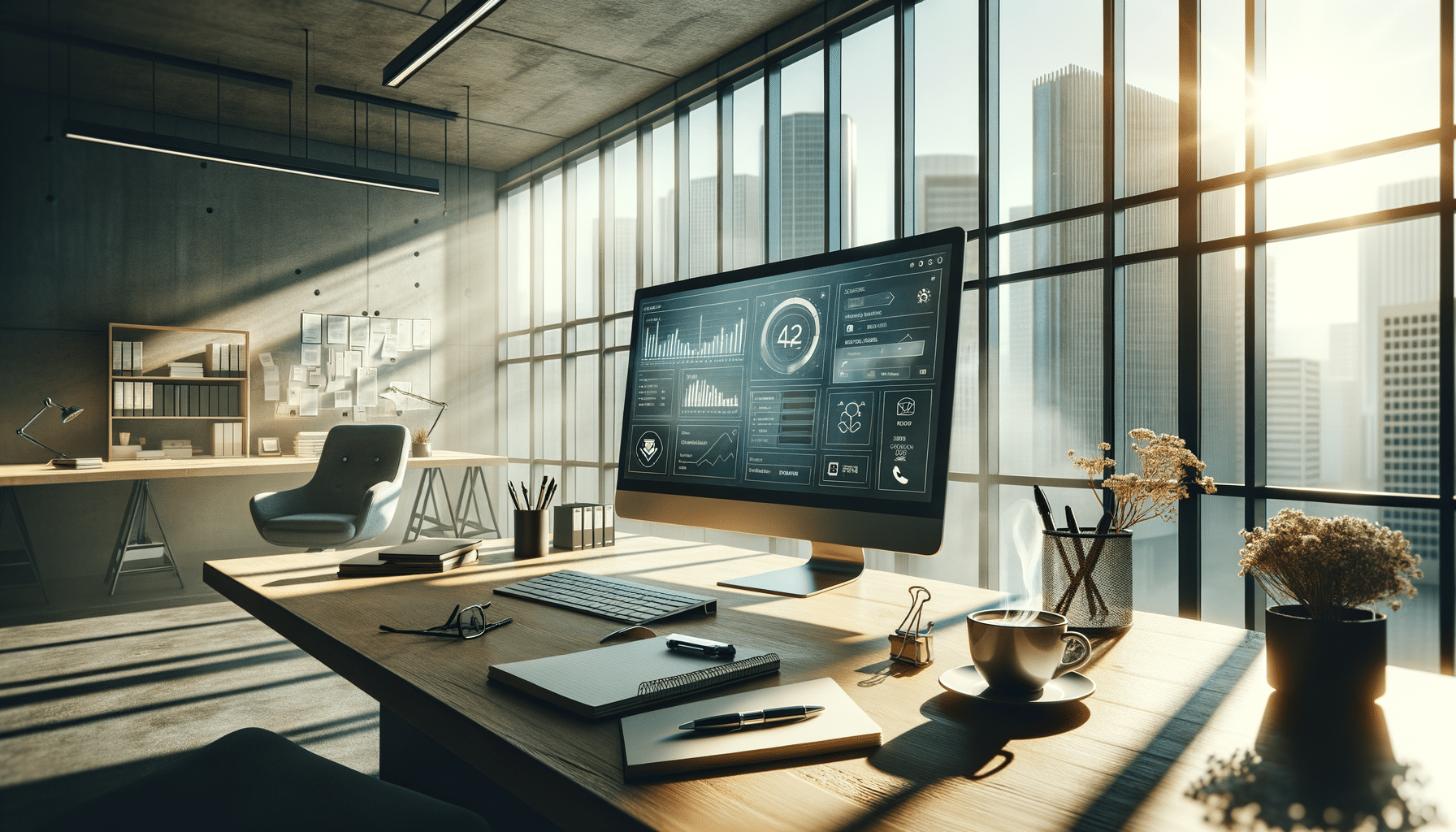

The field of industrial machinery is constantly evolving, with new technologies and innovations emerging to further enhance manufacturing capabilities. One notable trend is the integration of IoT (Internet of Things) technology into industrial machines, enabling real-time monitoring and data analysis. This connectivity allows for predictive maintenance, reducing downtime and extending the lifespan of machinery.

Another trend is the development of more sustainable machines that focus on energy efficiency and reduced environmental impact. Manufacturers are increasingly adopting eco-friendly practices, and industrial machines are being designed to support these initiatives by minimizing energy consumption and emissions.

Conclusion: The Future of Industrial Machines

As we look to the future, industrial machines will continue to play a critical role in the advancement of manufacturing technologies. Their ability to enhance productivity, ensure quality, and reduce costs makes them indispensable assets in any production environment. By embracing innovations and adapting to emerging trends, manufacturers can harness the full potential of industrial machines to stay competitive in a rapidly changing market. The continuous evolution of these machines promises exciting developments that will shape the future of manufacturing for years to come.